The Suggested Order Quantity (SOQ) is the number of units that a company should add to inventory with each order to minimize the total costs of inventory—such as holding costs, order costs, and shortage costs. The SOQ is used as part of a continuous review inventory system in which the level of inventory is monitored at all times and a fixed quantity is ordered each time the inventory level reaches a specific reorder point.

Sometimes called Economic Order Quantity (EOQ)

The time between receiving an order and delivering the product or service to the customer the time it takes to prepare, make or deliver.

The lead time is the delay applicable for inventory control purposes. This delay is typically the sum of the supply delay, that is, the time it takes a supplier to deliver the goods once an order is placed, and the reordering delay, which is the time until an ordering opportunity arises again. This lead time is usually computed in days.

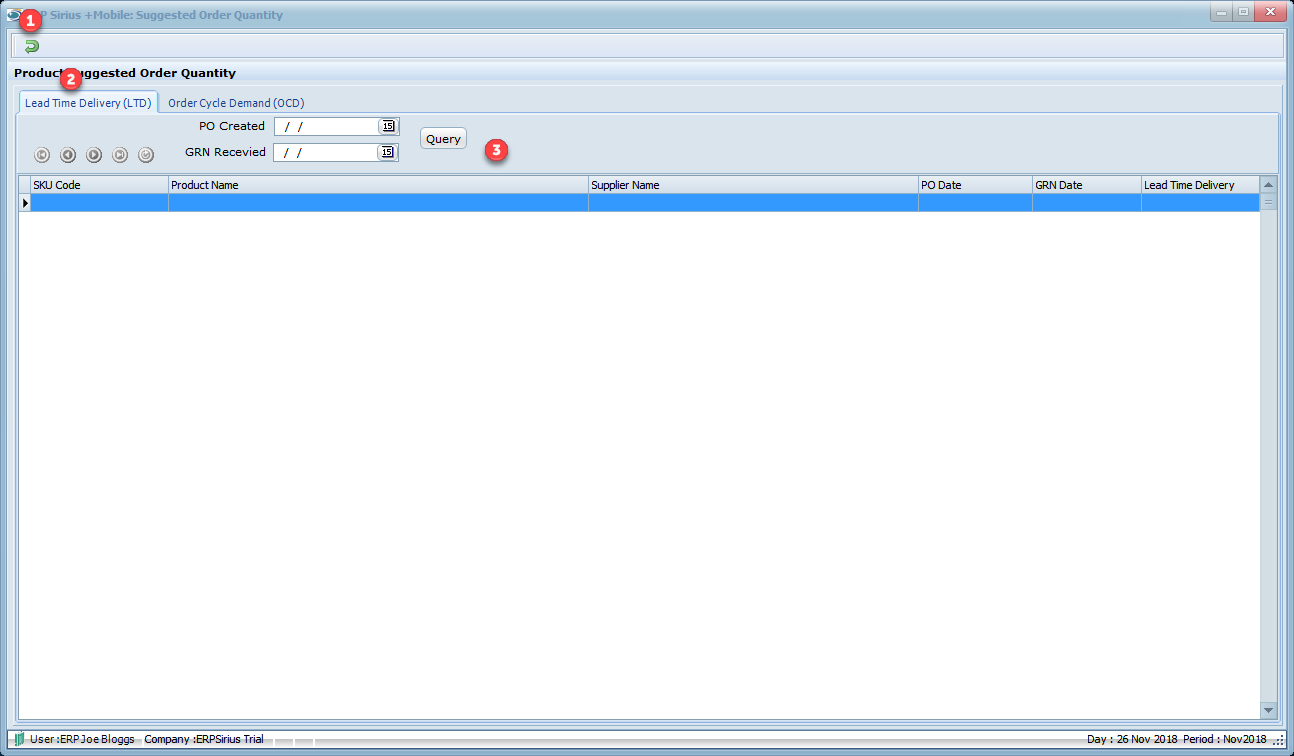

1.Exit or Cancel the current process.

2.Lead Delivery Time Tab.

3.Query and calculate Lead Delivery Times.

Order cycle time refers to the time period between placing of one order and the next order. It is the time period between two orders that are placed. The time period between placing of an order and receiving it is called the order lead time.

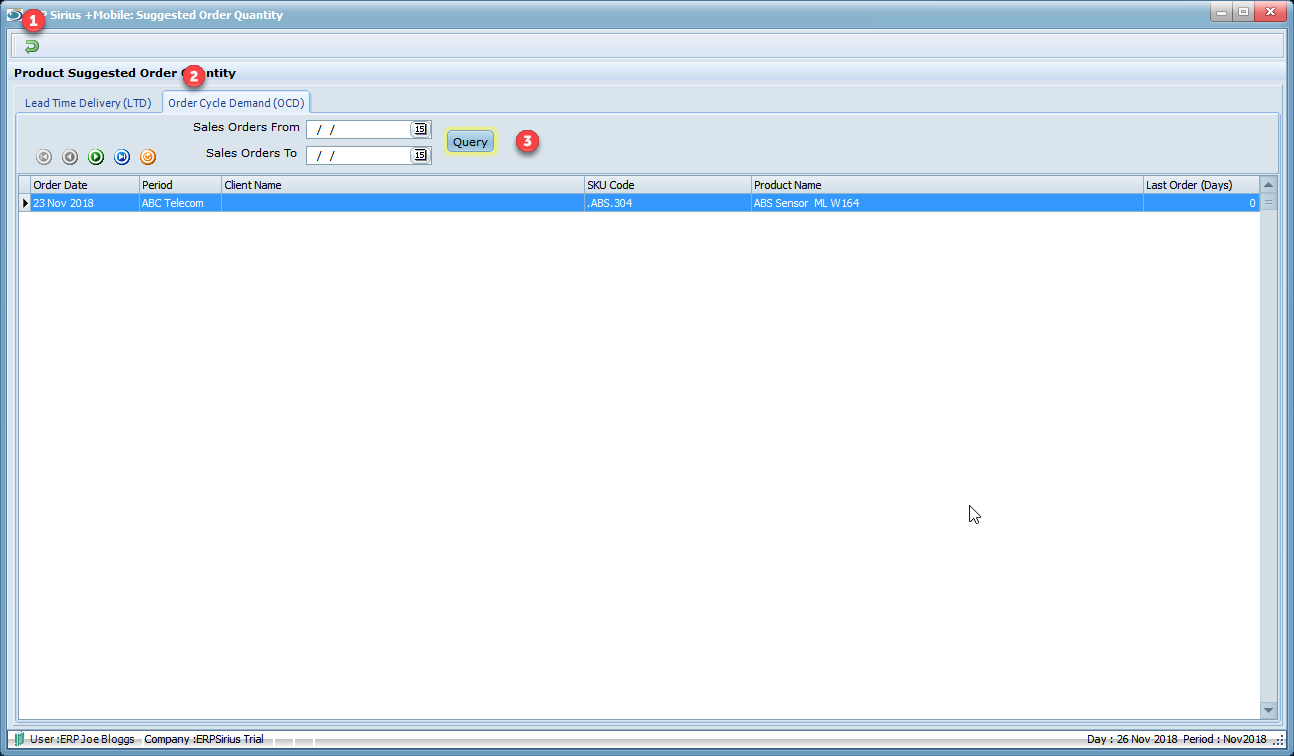

1.Exit or Cancel the current process.

2.Order Cycle Demand Tab.

3.Query and calculate Order Cycle Demand